_____________________________________________________

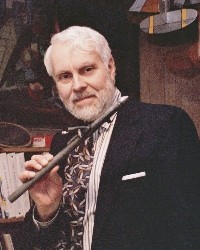

Note from the Editor:

In this feature of each issue, we'll feature one of my own

designs from our Gallery of Hopeful Monsters. These

will generally be jet engines or related equipment that are

PROPOSED designs that are as yet untested and unproven --

BUILD AT YOUR OWN RISK !!! No full-size plans, scale prints

or detail drawings, other than what we show here, are available.

Also, since these are usually just proposed designs that we haven't

even built ourselves, we offer almost no technical information --

these are definitely for advanced experimenters who are used to

working out the fine points on their own!

So, these designs are mostly presented to give you something to

think about, although advanced hobbyists can try to build them

and get them to run. Let us know if you have any amazing

successes to report!

One of my latest designs is the Reynstodyne(TM) Shark(TM) engine, so

called because of the rearward-sloping 'fin' intake. In this case,

the prototype actually has been built [as shown in the photos

below, with comments], but preliminary testing has not been very

conclusive [testing was cut short because my starting air

compressor bombed -- I now have a replacement, but it's been too

cold and wintery for the last couple of weeks to stand around

outside for testing].

A final note is that my friend Ben Brockert suggested lengthening

the tailpipe so it would be somewhat MORE than twice the length

of the front chamber. This opinion was based on his reading of the

great work of F. H. Reynst. I took his advice, not by lengthening the

tailpipe, but by shortening the chamber approximately 3/4 inch (18mm)

thus moving in the direction of being more compact, rather than

significantly longer. One of these days, it's going to warm up a little,

and then I'll find out what we've got here!

Stay tuned ... - Larry Cottrill

_____________________________________________________

The ReynstodyneTM 'Shark' tiny valveless pulsejet design

by Larry Cottrill

Copyright 2003 Larry Cottrill

REYNSTODYNETM 'SHARK' ENGINE

The original shark prototype drawing, as disclosed on 03 January 2003. In a recent modification,

the length of the ignition chamber has been reduced by taking out .75 inch in front of the

spark plug.

Drawing Copyright 2003 Cottrill Cyclodyne Corporation

Original disclosure 01/03/2003 on Kenneth Moller's Valveless Pulsejet Forum,

as follows:

[

Well, here's the latest -- the Reynstodyne(TM) 'Shark'(TM) prototype engine:

The drawing should be self-explanatory, but a couple of details bear a bit

more explanation:

The idea of the 'sharkfin' intake is that the easiest path provided for entering

air will be forward into the chamber. This does not mean that significant air

won't be diverted rearward to fill in the tailpipe behind the hot gas 'piston'

as it exits. The way you attach the intake venturi to the pipe is important.

You cut the slot in the top of the pipe MUCH larger than the cut off base of

the flattened tube venturi (so the venturi would actually fall down in!). Then,

you clamp the intake in place 'hovering' over the slot and tack weld in a couple

of spots by 'bridging' across the gap, then bend it around the tack welds a

little til it's lined up true with the tube centerline. Then, tack weld in a couple

more spots, and finish weld all around, again 'bridging' your weld across the

gap. What you end up with is a fairly smooth flow transition on the inside

where it counts. That sounds a lot trickier than it is -- the gap is only a

sixteenth of an inch or so, all around. It took about 20 minutes to do the whole

job. You make the intakes two at a time by flattening the middle of a short

piece of tubing to the 'just right' width, and then cut diagonally across the flat

with the jeweler's saw. Then, drill through for the needle valve --

simplicity itself.

The drawing shows the mounting plate as it would be on a production engine

(fin to the top) -- for testing purposes, I placed it on mine so the fin would be

on the left side and the plug on the right. That's why there are those 'ghost

images' of the mount in the 'prototype location'. Location and orientation of

this plate should be completely non-critical, except that I wouldn't put it up

front on the chamber somewhere because of its potential for heavy heat

conduction.

My insistence on having the sparkplug where the incoming carbureted air/fuel

stream washes over it may not be optimal -- it's just located that way because

I thought it would make for easy starting. Once the engine's running, the plug

should mean nothing, of course.

I did not include a football filler type air pipe aimed across the needle valve

and down the throat, though I may end up needing to add one. I decided that

I'd try starting the Shark either by blowing air in with a hand-held miniature

nozzle, or try just spraying fuel in from a pressure can, via a tiny tube

extended down through the intake throat! Based on my earlier experimentation,

the needle valve will probably need to be way open (5 or 6 full turns) for good

starting.

]

Recent design/change notes on this design:

- Current prototype has had the front chamber reduced in length by .75 inch

(18mm) from the drawing dimensions shown, to make certain the chamber

length is LESS THAN 1/2 the tailpipe length [ref: F. H. Reynst]

- It is probable that location of the sparkplug in the bottom of the chamber

is not good design, since it makes the plug potentially susceptible to fuel

flooding during starting; side location is probably better

- 'Football filler' starting air pipe was added to the intake to aim starting

air properly across the fuel port of the needle valve assembly; this resulted

in more reliable ignition during starting attempts

Prototype Engine Photos:

A COMPACT VALVELESS PULSEJET DESIGN

These shots show the completed SharkTM prototype engine, laid out by a tape rule (inches) -

original overall length as shown here was just over 15 inches [.4 m]. It has since been reduced

by .75 inch [18mm]. In the upper photo, the engine is shown mounted on the test frame, with

fuel tank [just behind engine tube] connected to the needle valve body.

Photos Copyright 2003 Cottrill Cyclodyne Corporation

THE SHARKTM IN PERSPECTIVE

The engine seen from the nose end [upper photo] and exhaust end [lower photo]. Note the

spark plug ahead of and opposite to the 'shark fin' intake tube. In the lower shot, the rim

of the rearward-facing intake opening is visible above the needle valve assembly.

Photos Copyright 2003 Cottrill Cyclodyne Corporation

NOZZLE ZONE AND INTAKE TUBE DETAILS

These shots show the slightly pinched nozzle area between the ignition chamber and tailpipe,

and details of how the flattened area of the intake tube is blended into the main tube in this

region. The needle valve body penetrates the intake tube through this narrow section. [An air

tube for starting was added later to the lower edge of the intake rim.]

Photos Copyright 2003 Cottrill Cyclodyne Corporation

IGNITION CHAMBER AND PLUG MOUNT DETAIL

Inverting the engine allows the plug mount and its relationship to the intake tube to be clearly

seen. During starting, the forced draft of fuel/air mixture will cross the tube and flow forward

down the side around the end of the spark plug. The plug mount is sufficiently thick that only the

spark electrodes of this long-reach plug are allowed to clutter the inside wall of the tube.

Photo Copyright 2003 Cottrill Cyclodyne Corporation

Theory of Operation

The SharkTM is what I refer to as a 'Reynst pattern' engine. What I mean

by this is a pulse combustion engine where the ignition chamber is

separated from the tailpipe by an air inlet, and where the front of the

chamber is closed and all breathing of the chamber to support combustion

takes place at its rear opening after expulsion of the explosion product

gases. This definition does not necessarily mean that all the air is taken

in from the gap [i.e. with none of it coming back in through the tailpipe], but

in fact that may actually be the case in such designs.

'Reynst pattern' devices are extremely efficient burners; in fact, F. H. Reynst

developed his famous 'Reynst pot' not as a propulsion device but rather as an

industrial burner for special heating applications. As such, the 'pot' itself

is not optimized for ejected mass at high velocity, but rather for efficiently

burning fuel and recovering the combustion energy as heat. However, efficient

combustion is one primary concern for a practical jet powerplant. It is hoped

that the design shown here will eject mass rapidly enough for good propulsive

force [thrust] while retaining a reasonable semblance to Reynst's high

efficiency mode of operation.

A non-mathematical description of a single operational cycle is as follows:

After the fuel/air charge explodes in the front end of the ignition chamber,

the extremely sudden pressure rise causes a rapid expansion which

compresses the air [or residual exhaust gas] in the rear of the chamber

and begins to accelerate this gas mass rearward.

As the gas mass accelerates rearward, the portion of gas that started

out inside the chamber passes through the relatively narrow nozzle zone,

which locally increases its rearward velocity and drops its static pressure.

The lowered static pressure prevents the gas from being ejected outward

through the intake port, since the outside air is at normal pressure. Thus,

beginning at this point in the cycle, the chamber is effectively 'valved

off' from the outside air and fuel. For all practical purposes, the exhaust

flow is not influenced by the presence of the air intake, and the engine

behaves as a continuous pipe closed at one end for this part of the

cycle.

As combustion within the rear of the moving gas mass continues, the gas

slows and regains static pressure as it exits the nozzle zone. Expansion

continues to drive the gas rearward, and the 'leading edge' of the gas mass

begins to exit through the tail end of the pipe.

At some point, practically all the explosion energy has been transferred to

the gas mass as rearward momentum [though a significant fraction has

been lost as heat to the metal engine shell]. At this point, the gas mass

acts as a 'piston' pulling the very low-density residue in the chamber

into a condition of 'overexpansion'; that is, the static pressure in the

chamber begins to drop.

Eventually, the gas mass has moved so far rearward that the overexpanded

area occupies the entire chamber and reaches into the nozzle zone and

covers the inside face of the intake tube. Because the overexpanded gas

has low static pressure, the outside air pressure begins pushing the air

in the intake tube inward into the interior of the engine. From this point

in the cycle, the chamber is "valved on" to fresh air and fuel! As air flows

in, it will be replaced by fresh air from the outside beyond the outer intake

rim. The behavior of the engine is now that of a short low-pressure

chamber open to standard pressure air via a narrow opening.

The whole air column in the intake is now in motion, and flow will continue

until the pressures again equalize; this will take a while because of the

volume of the chamber. Because the lower zone of the intake pipe is

flattened to a much smaller internal cross-section than the outer intake rim,

the air is accelerated to a much higher velocity in this region, and the static

pressure drops. This means that the liquid fuel present at the fuel port in

the needle valve body will be drawn into the airflow, since the fuel external

to the valve is at more-or-less outside air pressure. Because of the shear

and turbulence effects on the air as it passes around the needle valve body,

the fuel drawn in is immediately atomized, so it will be rapidly evaporated

into the air stream as it enters the engine.

As air/fuel mixture pours in, it is routed by the geometry of the intake pipe,

the nozzle and the chamber forward, deeper into the chamber. At the same

time, the main gas mass in the tailpipe continues outward, but some of its

'trailing edge' combustion is slowed and eventually pulled forward through

the nozzle zone into the chamber. Eventually, the material in the chamber

has sufficient density and pressure, and the proper fuel/air ratio to form an

explosive mixture that can be ignited.

The exhaust gas mass in the tailpipe is also influenced by the pressure

difference that has been developed. This pressure difference acts as a

force in the forward direction, and the exhaust mass as a whole starts to

slow down in response to this force. Whether this mass actually undergoes

reversal and begins pouring back into the chamber through the nozzle

depends entirely on how long it takes for standard pressure to be regained

in the chamber. At any rate, to some extent, the engine now behaves as

a short low-pressure chamber open to standard air pressure via a small

port and below-standard but increasing pressure gas via a significantly

larger opening.

The accumulated mixture, reaching approximately the static pressure of the

outside air, ignites explosively to begin the next cycle of operation.

[It is not perfectly understood whether ignition happens because of the

recycled gases pulled back in from the tailpipe or simply because of residual

"free radicals" in the chamber. Once the combustion chamber walls attain

high temperature, this may also affect the precise instant of ignition.

However, the composition, pressure and density of the mixture are probably

the biggest determining factors in the precise timing of the explosion.]

The complete cycle described above would take approximately 3 milliseconds,

with a pulse frequency of about 330 cycles/second, with the engine dimensions

shown in the drawing.

If you decide to try to build a working model of this experimental design,

make sure you get plenty of photos and email them to us in GIF or JPG

format to display in a future issue [we will make the final decision

as to the best ones to use, and we'll show your name as a photo credit.]

And, why not try writing an article about building and firing it? We

don't pay for articles, but we'd be glad to help you "get your name in

print". Also, any author whose article we accept gets a free ad for your

e-business or Web site! Naturally, we will provide editing as needed for

publication in readable US English.

- Larry Cottrill

|